- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

PRODUCT DESCRIPTION

CARBON STEEL SEAMLESS ROUND PIPE SUPPLIER | ZHONGJING

CARBON STEEL SEAMLESS ROUND PIPE SUPPLIER | ZHONGJING 【Specification】:10MM*20MM~700MM*300MM;customization size

【Length】:6M,8M,12M;Support customization

【Thickness】: 0.6mm~25mm

【Material】:Carbon steel

【Surface】: black

【Standard】:AISI;ASTM:GB;DIN;BS;JIS

【MOQ】: 5 TON

【Processing Service】:Bending, Welding, Punching, Cutting

【Transport Package】 : Water Proof Paper Suitable for Transportation

【Application】:Seamless carbon steel boiler and superheater tubes for high-pressure service.

ASTM A192 Seamless Tubes are high-quality low-carbon steel tubes, with a carbon content ranging from 0.06% to 0.18% and a manganese content between 0.27% and 0.63%. These tubes, often referred to as mild steel pipes, are widely used in a variety of applications due to their excellent formability and cost-effectiveness. Manufactured in compliance with ASME specifications, these tubes are ideal for use in high-pressure boiler systems and other industrial applications. They are commonly known as carbon steel (CS) or mild steel (MS) pipes and are easier to shape compared to higher-carbon steel pipes.

The ASTM A192 specification covers seamless carbon steel boiler tubes designed for high-pressure service. These tubes are suitable for use in pipelines, thermal technology equipment, industrial machinery, petroleum exploration, and the chemical industry, among others. Their low carbon content contributes to a balance of strength and malleability, making them versatile and adaptable to various processing needs. Carburizing can be used to enhance the surface hardness of these pipes, should that be required for specific applications.

FerroPipE is a trusted supplier of ASTM A192 seamless tubes, offering a comprehensive range of IBR Certified tubes with outer diameters from ½” to 24” and nominal bore sizes from 15NB to 600NB. These tubes are stocked and distributed worldwide, including to regions like Iran, Iraq, Kuwait, Qatar, South Africa, Nigeria, Saudi Arabia, Australia, Canada, and Mexico. Whether for domestic or international applications, FerroPipE ensures high-quality products with careful attention to material grade, chemical composition, and surface condition.

ASTM A192 steel tubes offer outstanding performance in demanding environments. They are highly resistant to high temperatures, ensuring reliable operation and long service life in boiler applications. With excellent strength, these tubes can withstand high-pressure conditions without deformation or failure. Additionally, their corrosion resistance makes them ideal for use in corrosive environments, providing durability and consistent performance across various industrial applications.

ASTM A192 seamless steel tubes are widely used across various industries due to their exceptional properties. These tubes are commonly found in power generation plants, where they are utilized for boiler applications. Their ability to withstand high temperatures and pressures makes them ideal for generating steam, which drives turbines and produces electricity.

In the petrochemical industry, ASTM A192 tubes are employed in refinery processes, chemical plants, and oil and gas processing, offering reliable heat transfer and resistance to corrosive environments. This ensures efficient operation and long-term durability in harsh conditions.

These tubes are also essential in heat exchangers, where they facilitate efficient heat transfer between high-temperature fluids, supporting various industrial processes that require heat exchange. Additionally, ASTM A192 tubes are used extensively in industrial boilers, heating systems, and power plants, where they effectively transfer heat from the combustion chamber to the water, enabling reliable steam generation.

In the automotive industry, these tubes are incorporated in high-performance engines, particularly in racing vehicles. They are used in intercoolers and exhaust systems, enhancing heat dissipation and optimizing engine performance for improved efficiency and power output.

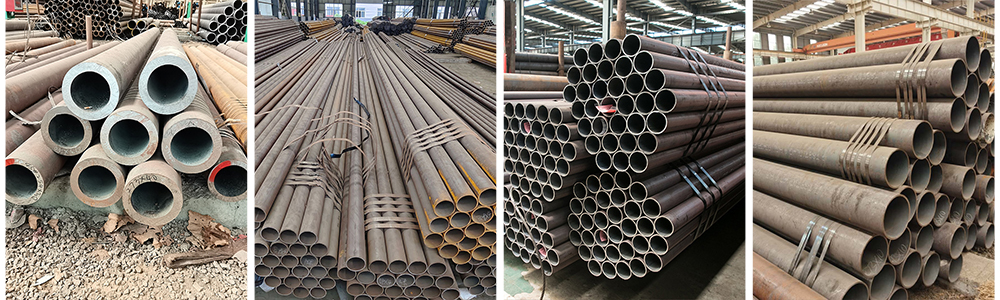

PRODUCT SHOW

| C, % | Mn, % | P, % | S, % |

| 0.06-0.18 | 0.27-0.63 | 0.035 max | 0.035 max |

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % | Hardness, HB, WT≥5.1mm | Hardness, HRB, WT<5.1mm |

| 325 min | 180 min | 35 min | 137 max | 77 max |

Standard:ASTM A192, ASME SA192

Equivalent Standards: EN 10216-2, DIN 17175, BS 3059 Part II, NF A 49-213, NBR 5594

Material: SA192

Equivalent Materials: 1010, St35.8, 360

| Outside Diameter, mm | Tolerance, mm |

| 3.2≤OD< 25.4 | ±0.10 |

| 25.4≤OD≤38.1 | ±0.15 |

| 38.1 OD 50.8 | ±0.20 |

| 50.8≤OD< 63.5 | ±0.25 |

| 63.5≤OD< 76.2 | ±0.30 |

| 76.2 | ±0.38 |

| Hot rolle | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | |

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD≤101.6, WT>4.6 | +28/-0 | |

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | |

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | |

| OD>101.6, WT>4.6 | +28/-0 | |

| Cold Drawn | Outside Diameter, mm | Tolerance, % |

| OD≤38.1 | +20/-0 | |

| OD>38.1 | +22/-0 |

Zhongjing Steel Group (Guangdong) Co.,Ltd. specializes in the production of cold-rolled/hot-rolled coils, carbon steel pipes, bars, and PPGI materials. It is a modern enterprise integrating carbon steel production, processing, and trade. It is a Chinese iron and steel enterprise group.